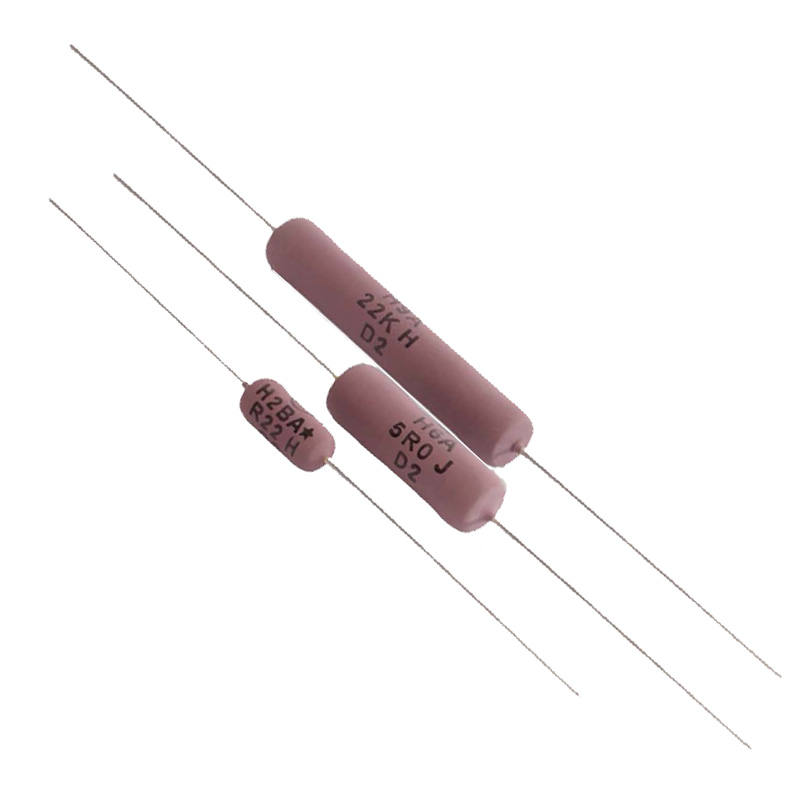

HTR: HTA Series, Axial Wirewound – Possible Vitreous Enamel Replacement

When looking to specify power wirewound resistors, users tend to select products which have performed well in the past and when considering an alternative technology, if the outcome hasn’t been as desired, this further compounds the use of the old technology.

One example is when users look to replace vitreous enamel wirewound resistors, this is a proven well established technology, but due to the declining need for power resistors, the price has increased significantly to offset the overall sales. Also from an environmental standpoint, as the firing of the vitreous enamel requires temperatures of +750 °C, the environmental impact starts to quickly escalate, alongside the cost.

In response to this need, HTR have developed their Power Silicone “Thermo Coat”. This coating provides users with at least or in many instances improved performance characteristics, including; power to size ratio, TCR & load life compared to the vitreous enamel counterpart, the “Thermo Coat” is less fragile resulting in reduced chance of damage. Wirewound resistors are commonly used for pulse / overload & fusing applications, not only are HTR able to optimise the HTR: HTA Series to handle the user’s specific circuit demand, the self-extinguishing coating which utilises Japanese UL approved silicone resins; helps to meet the safety approval requirements placed on overall product designs.

There are only some very limited applications, whereas the environment is extremely harsh, such as areas of high humidity, when “salt spray” is present or if the resistors will be immersed in oil and for these instances; vitreous enamel is the best choice.

With power ratings up to 12W @ 70°C, ohmic values from R10 to 100kohms, tolerances to 1% & TCR’s of < 100 ppm/Deg°C the HTR: HTA Series can be considered for cost conscious new designs, but also as a replacement item.

If you like the look of the HTR: HTA Series, please get in touch with DMTL to discuss your requirement / request free of charge samples.