Laser Direct Structuring (LDS) Technology

Laser Direct Structuring (LDS) is a manufacturing process in which a conductive trace can be implemented directly on an injection-molded plastic.

The key benefit of this technology compared to the traditional technologies (Stamped Metal or Flexible Printed Circuit) is that the LDS process allows full 3D structures, therefore enabling the flexibility to integrate complex mechanical designs in miniature 3D shapes.

This manufacturing technology is ideal when more curves are needed or less 3D volume is available. For antennas, this means the possibility to design more complex designs, reduce assembly costs or have the antenna outside the device, therefore enhancing the wireless performance while maintaining small form factors.

How It Works

- LDS suitable resin is loaded with additives and molded to the desired shapes with traditional molding tools.

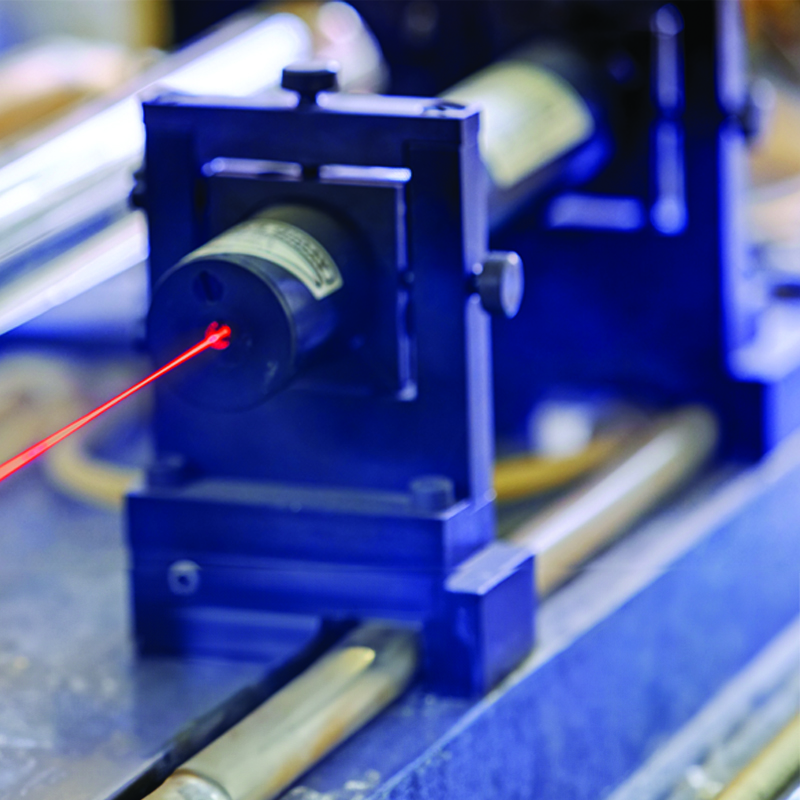

- Laser Processing machine is preloaded with the 3D pattern of the needed shape.

- The laser process activates the additives in the molded part leaving a visible “burnt” trace.

- Plating process deposits Copper (Cu) &/or Nickel (Ni) &/or Silver (Ag) &/or Gold (Au) over the lasered area to create the RF and/or electrical trace

Key Benefits

- Full 3D Technology

- Flexibility to design smaller and thinner devices

- Conformal designs

- Multi-layer LDS | KYOCERA AVX Unique Solution!

- Possibility to design antennas directly on the device housing

- Gain 3D volume for the antennas

- Save space on the board

- Improved RF Performance

- Combine several antennas on the same 3D structure

- Increase the distance between the antenna and other components

- Unique antenna patterns and shapes

- Manufacturing Advantages

- Flexibility to optimise the pattern design without additional tooling costs

- Reduction of assembly costs in mass production

- Light weight

- SMT (Surface Mount Technology) possible for antennas

- Soldering of SMD components (e.g. matching components) or cables possible

- Painting process for cosmetics available

LDS Process

The process of LDS consists of 3 major phases: Injection Molding, Lasering Activation and Metallization. In some cases, there are additional steps like SMT process or soldering for the assembly of components.

For deeper insights into the LDS process, check out the whitepaper: Working Principles & Benefits for RF Applications

Related Articles

SuperCapacitors | Pros & Cons | Why Choose a SuperCapacitor?

Take a look at the pros and cons of SuperCapacitors and the different series AVX offer

Read more >

DMTL | The Special Distributor

DMTL operate successfully with companies of all sizes, we provide the support for products which need to be identified, handled and supported very differently from commodity products

Read more >

DMTL Now Certified to AS9120

DMTL have successfully transitioned from ISO 9001:2015 to AS9120 RevB (EN 9120:2018) following requests from their growing Hi-Rel customer base.

Read more >

Laser Direct Structuring (LDS) / Moulded Interconnect Devices (MID) for custom Antennas and unique Electromechanical solutions

DMTL are now able to offer limitless possibilities of Antenna design and support with Ethertronics offering of Laser Direct Structuring (LDS)

Read more >

A History of DMTL - Founded in 1987...

Throughout the years, DMTL have advertised in many publications and here is a brief history of some of the adverts designed and published by DMTL!

Read more >